In the age of personalized products, the demand for high-quality printing solutions has boomed like never before. One technology that stands at the forefront of this revolution is Direct to Film (DTF) printing. This innovative printing method is rapidly gaining traction among entrepreneurs and creatives alike, as it allows for an array of printing options on various materials, especially through print on demand services. Today, we will explore the ins and outs of DTF printing technology, including its benefits, the process, and how you can leverage it for your own customized designs.

What is Direct to Film Printing?

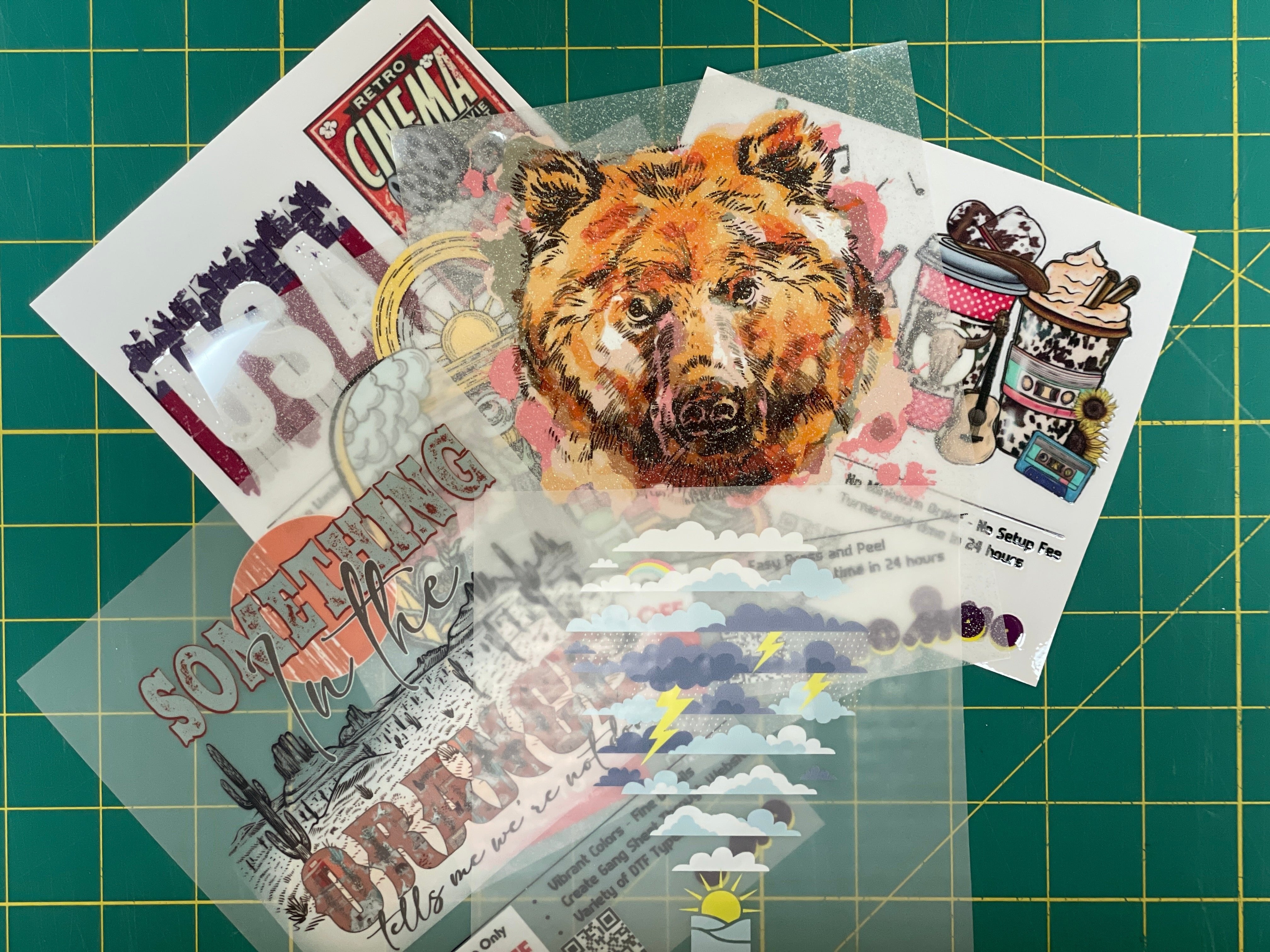

Direct to Film (DTF) printing is a cutting-edge printing technique that transfers vibrant images onto a film which is then used to apply the design onto textiles, garments, and other surfaces. Unlike traditional printing methods such as screen printing or DTG (Direct to Garment), DTF uses a specialized printer that lays down both adhesive and ink onto a transfer film, enabling the creation of bright and intricate designs. This technology's ability to produce vivid color palettes and fine details makes it an appealing choice for creators and businesses looking to stand out.

The Benefits of DTF Printing

High-Quality Output

One of the most remarkable features of DTF printing is the ability to produce high-quality prints with vivid color accuracy. The technology uses water-based inks that are eco-friendly and have excellent opacity, allowing for vibrant designs even on dark fabrics. Glitter DTF printing adds a sparkling effect to designs, giving them extra dimension and making them perfect for custom apparel.

Versatility in Material

DTF printing is incredibly versatile; you can print on various materials including cotton, polyester, blends, and even leather. This broad compatibility opens doors for creative entrepreneurs to explore numerous product offerings without worrying about the limitations often associated with traditional printing. Whether it's t-shirts, hoodies, tote bags, or caps, DTF can handle them all.

Cost-Effective and Efficient

With a print on demand model, you can minimize your upfront costs, as there is no need to maintain large inventories. DTF printing requires less setup time compared to screen printing, making it a more efficient option for both small and large runs. This process allows for quicker turnarounds, which is vital for businesses needing fast delivery solutions.

Durability

DTF prints boast remarkable durability. The designs can withstand multiple washes and are less prone to cracking or peeling than other printing options. This longevity ensures your customers are satisfied with their customized designs and helps maintain your brand’s reputation for quality.

The DTF Printing Process

The process of DTF printing involves a few key steps which combine technology and artistry.

Step 1: Design Creation

The first step in DTF printing is creating your design using graphic design software. This is where you can unleash your creativity and produce customized designs that appeal to your target audience. Considerations like color choice, size, and intricacy play a crucial role in ensuring a successful print.

Step 2: Printing the Design onto Film

Once your design is ready, it is printed onto a special transfer film using a DTF printer. The printer uses color inks and a specialized adhesive that adheres the ink to the film. It's essential to ensure that a high-quality printer is used during this step to achieve the best results.

Step 3: Powder Adhesive Application

After the design is printed onto the film, a fine powder adhesive is applied evenly on top of the printed area. This step is crucial as it ensures that the design adheres well to the fabric during the heat transfer process.

Step 4: Curing the Adhesive

The film is then heated to cure the adhesive. This can be done using a heat press or an oven. The curing process ensures that the design is bonded firmly to the film, ready for application onto the final product.

Step 5: Transfer to the Fabric

The film can finally be applied to the textile or garment using a heat press. The heat and pressure cause the adhesive to bond with the fabric, transferring the design perfectly. After cooling down, the transfer film is peeled away, revealing a stunning and vibrant print.

Getting Started with DTF Equipment Sales

If you are keen on entering the world of DTF printing, the right equipment is necessary to kickstart your journey. The key components you need include:

- DTF Printer: Specifically designed printers that produce high fidelity prints.

- Curing Ovens or Heat Press: To cure powder adhesive and transfer designs.

- Transfer Films: Specially coated films formulated for DTF processes.

- Adhesive Powder: To ensure that prints adhere firmly to the fabric.

Investing in quality dtf equipment sales ensures that you can deliver high-quality prints while maintaining efficiency in your operations. With numerous suppliers available, it’s essential to research and choose quality equipment that will scale with your business needs.

Exploring Niche Markets with DTF Printing

DTF printing isn’t just a technology; it's an opportunity to explore various niche markets. Here are some ideas:

- Custom Apparel: Create personalized clothing for events, businesses, or gifts.

- Corporate Branding: Offer customized branded merchandise for companies.

- DIY Kits: Provide kits for customers to create their own custom designs at home.

- Art Prints: Use DTF technology to create stunning wall art or canvas prints.

By tapping into these niche markets, you can create a unique brand identity while providing high-demand products that leverage the capabilities of DTF printing.

Taking Your DTF Prints to the Next Level

To truly shine in the print on demand industry, consider implementing innovative practices that will enhance your DTF offerings. Here are some tips:

- Embrace Trends: Always be on the lookout for trending designs and themes. Trends can evolve quickly, and being adaptable can significantly boost sales.

- Market Your Brand: Utilize social media, email marketing, and other channels to showcase your designs and foster engagement with customers.

- Collaborate with Artists: Team up with graphic designers to produce limited edition prints. These exclusive designs can create buzz and drive sales.

- Offer Customization: Allow customers to tweak designs or add personal touches to make products their own.

Incorporating these strategies into your business can help set your brand apart in the competitive landscape, leading to increased visibility and profitability.

Your Path Forward in DTF Printing

Whether you are a seasoned business owner looking to diversify your offerings or a newcomer eager to explore the world of custom designs, DTF printing offers an exciting avenue for creativity and commerce. By investing time in understanding and implementing DTF technology, you can tap into the growing demand for personalized, vibrant products, positioning yourself as a leader in the printing space.

Embrace the future of printing with DTF technology and watch your creative business ideas flourish. With the right equipment and a keen eye for design trends, the possibilities are endless. Let your creativity soar and transform your visions into stunning, customized designs for every customer!